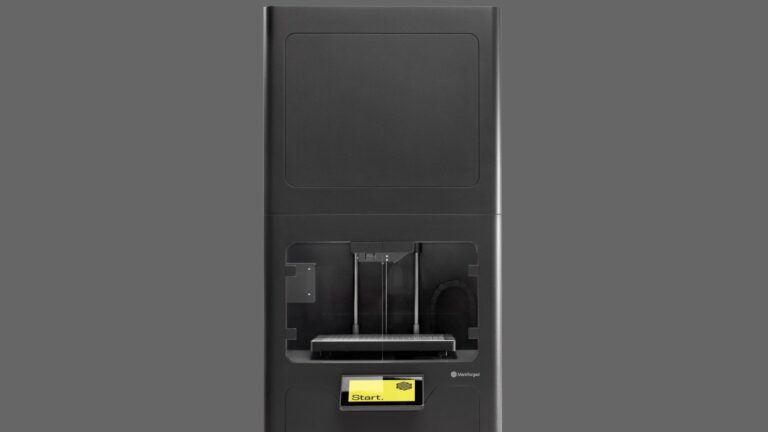

The FX20 is the largest, fastest, and most sophisticated 3D printer Markforged has ever created. Engineered from the ground up for unparalleled performance and reliability, the FX20 large format 3D printer takes our patented composites technology to a larger scale, creating new possibilities for new applications and industries. Capable of printing high-temperature thermoplastics with the continuous carbon fiber, it delivers high-strength aerospace-grade parts at the push of a button.

Larger and heated installation space for your applications

An even larger and heated installation space ensures components of the highest quality. Includes a heated build chamber capable of maintaining a temperature of up to 200°C.

Prints up to 8x faster than the default print settings of existing Markforged composite printers.

– Large material spools with 3200 cm²

– 3 nozzle print head

– Precision ground vacuum bed

– Reusable print sheets

– Touch screen interface

Even more stable components with ULTEMTM 9085 filament

Built for everything from high-performance tools and jigs to ready-to-fly production parts, the FX20 is the first 3D printer in the Markforged family to be able to reinforce ULTEM™ 9085 filament with continuous carbon fiber.

The material is particularly characterized by its high heat and chemical resistance and also has the highest tensile and flexural strength.

In addition, of course, the conventional materials can be printed such as Onyx, Onyx FR, Onyx ESD, Nylon White and a support material for ULTEM TM 9085, the ULTEM TM Filament Support.

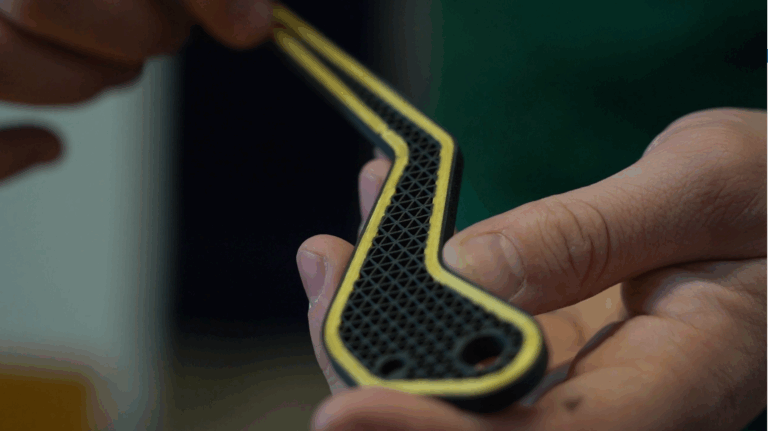

In the picture on the left is our colleague Jan Geese, Head of Application Engineering, with a feeding shoe from PLAN4 Engineering GmbH. The part was printed on the Markforged FX20 in around 66 hours with the dimensions 501 x 396 x 344 mm and 3160 cm³ Onyx.

The “ULTEM™ and 9085 trademarks are used under license from SABIC, its affiliates or subsidiaries.